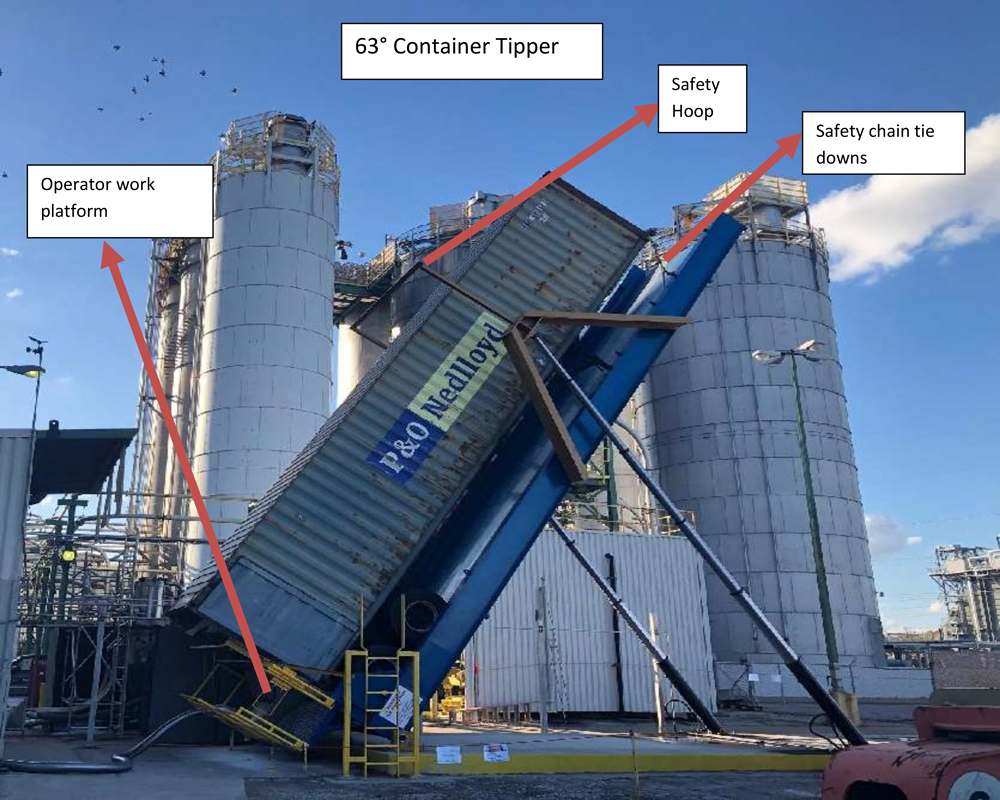

American International tilters offer a better container unloading process than tilting trailers and are suited for food products (including sugar, grain, rice, soybeans, and coffee), minerals (nickel, coal, lime, cement), and polymers (resins, PET, PE, PP, recycling).

American International container unloaders are versatile and can unload 20’, 40’, and even 53’ shipping containers for a wide range of bulk materials. This system allows you to increase operational productivity while improving safety and avoiding contamination risks caused by double handling imported material.

Click here for more information on our container-only tipper (no chassis).

Click below for information on our container tilter and container-only tipper.

View PDF Container Info Card

Benefits of these tipper units include:

- Lower labor costs: Uses a single operator.

- No contamination risks: Unload directly into silo/storage.

- No more tilting trailers: Eliminates the need to find expensive tilting trailers.

- Safer: Options for safety hoops and safety tiedown chains for extreme full tilt over 45 degrees.

- More convenient: Unload containers when you want.

- More control: Adjust tilt angle to control unload speed.

- Easier to store: Containers can be stored in the tilter and unloaded over a longer time.

- Adverse weather protection: The snow protector at the top of the container prevents snow slide during tilting.

Economically responsible companies prefer bulk. Each time you unload a bulk container, you save more than $2,200 when compared to super sacks, resulting in millions of dollars in savings each year. Other benefits include:

- Safer operation

- Less mobile equipment

- Eliminates contamination

- One-man operation

- Convenient unloading